A Day at the Print Shop

by Gary Olsen

don't know

about you, but I love the printing process. I even ran my own printing

press many years ago when I was working for a local radio station. I was

a disc jockey in a previous life. I wanted to produce a weekly music survey

and distribute it to local record stores. Our program director acquired

an old multilith printing press that had seen better days, and I learned

how to make plates and print my surveys. The press was constantly breaking

down, and I was covered with ink every time I worked with the thing. I

didn't have a single shirt or pair of pants in my wardrobe that didn't

have ink on it. I loved every minute of it.

don't know

about you, but I love the printing process. I even ran my own printing

press many years ago when I was working for a local radio station. I was

a disc jockey in a previous life. I wanted to produce a weekly music survey

and distribute it to local record stores. Our program director acquired

an old multilith printing press that had seen better days, and I learned

how to make plates and print my surveys. The press was constantly breaking

down, and I was covered with ink every time I worked with the thing. I

didn't have a single shirt or pair of pants in my wardrobe that didn't

have ink on it. I loved every minute of it.

I

guess once you have printer's ink in your veins, you are inexorably linked

to the "black art." I call it that because there are still many

things about printing that remain a magical mystery to me. Such is the

case with this particular job, the Stained Glass Print and the Calendar

project. Bryce Parks, my partner on this project, and I had more than

our hands full getting the design just right, and thanks to computer technology,

we were able to produce a pretty good pre-press product. At some point,

however, one must rely on someone highly skilled in the reproductive arts

to make the design a reality... someone you can trust. Such a firm is

Union Hoermann Press in our home town of Dubuque, Iowa. Four generations

in the printing business, Union Hoermann has long been known for high

quality. They have excellent technology, and they are incredibly tolerant

of artists like myself. All the ingredients for a long and successful

relationship that has lasted more than 20 years. People like Randy Sigman,

whose family owns U-H, is great to work with.

I

guess once you have printer's ink in your veins, you are inexorably linked

to the "black art." I call it that because there are still many

things about printing that remain a magical mystery to me. Such is the

case with this particular job, the Stained Glass Print and the Calendar

project. Bryce Parks, my partner on this project, and I had more than

our hands full getting the design just right, and thanks to computer technology,

we were able to produce a pretty good pre-press product. At some point,

however, one must rely on someone highly skilled in the reproductive arts

to make the design a reality... someone you can trust. Such a firm is

Union Hoermann Press in our home town of Dubuque, Iowa. Four generations

in the printing business, Union Hoermann has long been known for high

quality. They have excellent technology, and they are incredibly tolerant

of artists like myself. All the ingredients for a long and successful

relationship that has lasted more than 20 years. People like Randy Sigman,

whose family owns U-H, is great to work with.

Above

left is Bryan Sigman inspecting one of the laysheets before trimming.

At right is Mike Thill with yours truly holding up one of the first untrimmed

prints. Bryan and Randy's father, Jim Sigman, took this photo which is

not bad considering I don't believe he has ever worked a digital camera

before.

Above

left is Bryan Sigman inspecting one of the laysheets before trimming.

At right is Mike Thill with yours truly holding up one of the first untrimmed

prints. Bryan and Randy's father, Jim Sigman, took this photo which is

not bad considering I don't believe he has ever worked a digital camera

before.

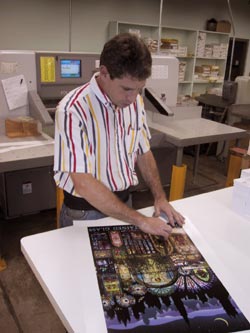

Mike

Thill (left) is setting up the job while I look over the pre-trimmed sheets.

That's 1,000 prints sitting there on the palette. Wow. What's so cool

is the smell. It's all part of the multi-sensory experience that's a print

shop. There is this constant din of the presses. Rare is the moment when

the shop is totally quiet. There's always some machinery running. At right

is Mike measuring the white space around the outside of the image area.

We elected to leave a more generous border than originally planned. You

can always make the print's over all dimensions smaller, but you can't

make the print larger after you've trimmed it down.

Mike

Thill (left) is setting up the job while I look over the pre-trimmed sheets.

That's 1,000 prints sitting there on the palette. Wow. What's so cool

is the smell. It's all part of the multi-sensory experience that's a print

shop. There is this constant din of the presses. Rare is the moment when

the shop is totally quiet. There's always some machinery running. At right

is Mike measuring the white space around the outside of the image area.

We elected to leave a more generous border than originally planned. You

can always make the print's over all dimensions smaller, but you can't

make the print larger after you've trimmed it down.

At

left is printer, Ryan Reeg. Ryan is an experienced pressman on the largest

four-head printing press at Union Hoermann. The huge Heidelberg press

floats on its own insulated concrete foundation because when it runs at

high speed, the vibrations could shake the building apart. The press uses

the most advanced color control and calibration devices. See those switches

below his left hand? They control the amount of ink that flows from each

ink reservoir, and it stores it digitally. On large jobs that may run

over a period of days,

At

left is printer, Ryan Reeg. Ryan is an experienced pressman on the largest

four-head printing press at Union Hoermann. The huge Heidelberg press

floats on its own insulated concrete foundation because when it runs at

high speed, the vibrations could shake the building apart. The press uses

the most advanced color control and calibration devices. See those switches

below his left hand? They control the amount of ink that flows from each

ink reservoir, and it stores it digitally. On large jobs that may run

over a period of days,  Ryan

can measure the color being applied to the press and match it perfectly

from day to day.

Ryan

can measure the color being applied to the press and match it perfectly

from day to day.

One of the neat things about working with Union Hoermann Press is they allow me free and easy access to all of their skilled people. This greatly speeds communication, and allows us to make decisions about the job right there in the shop... no delays. I tell them when I have a job in the shop, I want to be called for anything. I'll drop what I'm doing and go right down. There's a good deal of money at stake, and when you have these people working for you, you don't want to hold things up by being unavailable.

This

is the production manager at Union Hoermann, Sam Terwilleger. Sam and

I have worked on many a project together. This, we would have to agree,

is one the best. Here we are checking make-ready sheets from the press.

That's my Palm Pilot in the photo. I'm always taking notes on the job

for use later. Besides taking a camera along on these rides, I always

have my Pilot.

This

is the production manager at Union Hoermann, Sam Terwilleger. Sam and

I have worked on many a project together. This, we would have to agree,

is one the best. Here we are checking make-ready sheets from the press.

That's my Palm Pilot in the photo. I'm always taking notes on the job

for use later. Besides taking a camera along on these rides, I always

have my Pilot.

![]() Stained

Glass Project Media Kit

Stained

Glass Project Media Kit

![]() Key

to Images used in the Print

Key

to Images used in the Print

| © Gary Olsen 2014 all rights reserved. All graphics and copy in this Web site are the intellectual property of Gary Olsen and/or his clients' property, used with permission, and cannot be used for any purpose without permission. Address correspondence to olsega@mchsi.com. |